1 / 4

1 / 4Filling line for processing plastic bottles

Hardware Price:

ROI

6

months

savings potential

3.200 €

per month

DOF

3

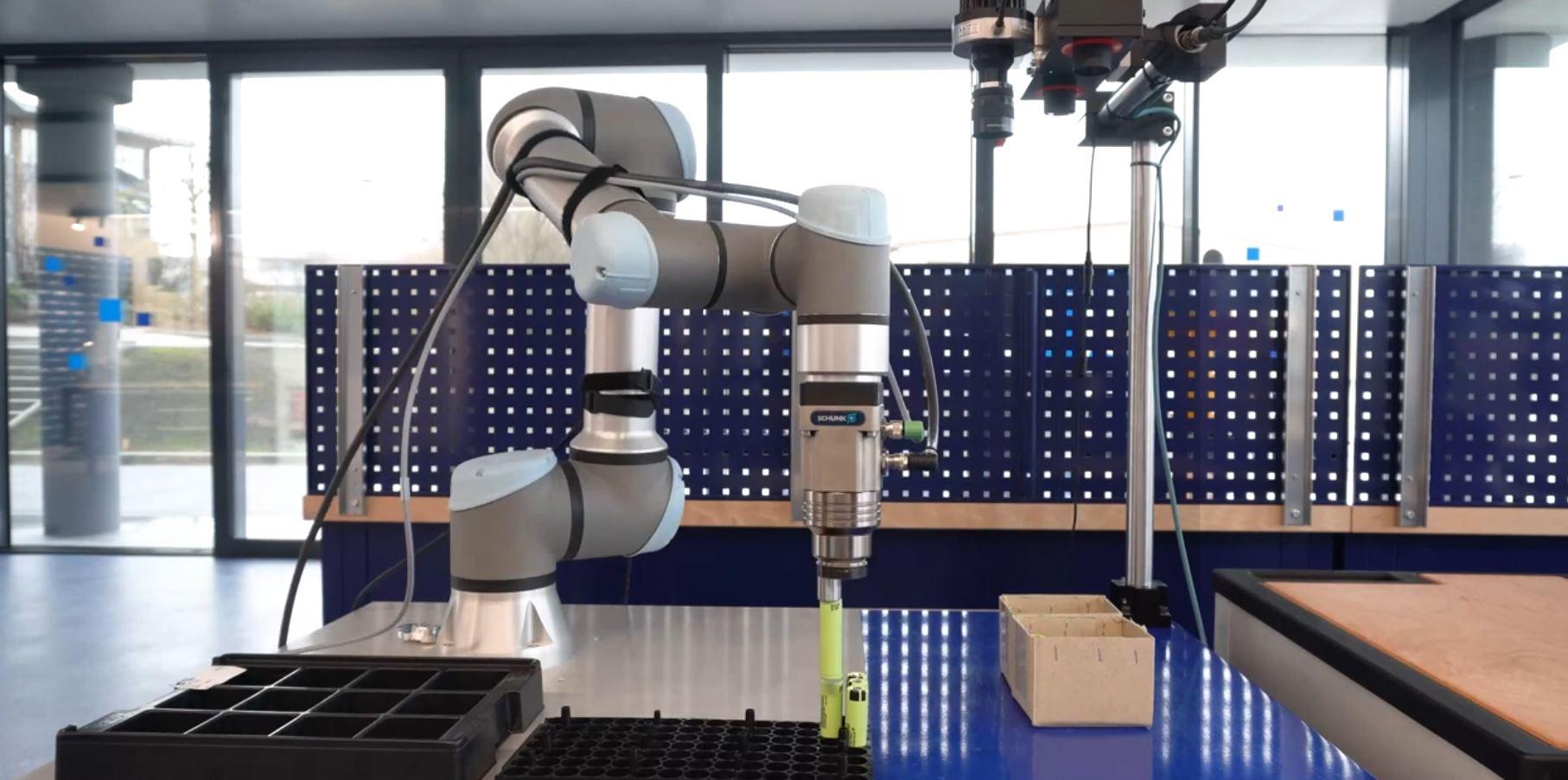

Automating Plastic Bottle Processing with Delta Robots: Precision and Efficiency

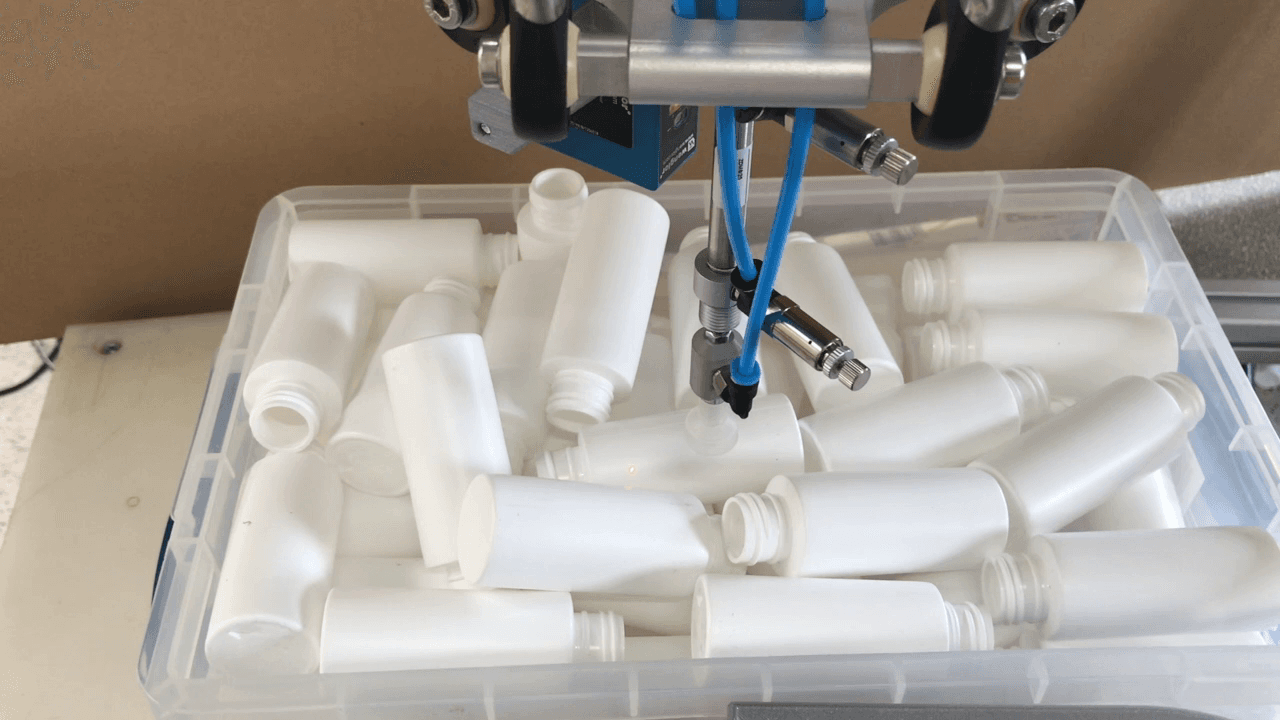

Automating the feeding of plastic bottles and caps improves efficiency in high-speed production lines. Previously, employees manually placed bottles and caps onto a conveyor, a process that required significant labor and adaptation during product changeovers. With the integration of Delta robots, these repetitive tasks are automated, ensuring consistent feeding from disordered cartons into the machine, which fills, labels, and seals the bottles before final packaging.

What is the Application?

Delta robots automate the placement of bottles and caps onto a processing conveyor. Using object recognition, the system handles cylindrical products of various sizes, making it ideal for frequent product changes.

What are the Advantages of the Solution?

Flexible Adaptability: Quick changeovers accommodate different product types.

Cost Savings: Reduces reliance on temporary labor, lowering operational costs.

Consistency: Ensures reliable, repeatable feeding, minimizing errors.

What are the Advantages of the Robot?

Delta robots offer multiple benefits tailored to this application:

High-Speed Precision: Handles objects quickly, matching cycle times of a few seconds.

Reduced Development Costs: 3D printing simplifies part production and spare availability.

Compact Design: Fits seamlessly into compact production setups.

Boosting ROI through Robotic Automation

The integration of Delta robots transforms bottle processing with improved efficiency and lower costs. With automation costs estimated at around €10,000 per cell, and personnel savings of €3,200 per month, the return on investment can be achieved within 6 months. This solution offers a scalable, cost-effective automation approach for modern production lines.

4 Components