1 / 3

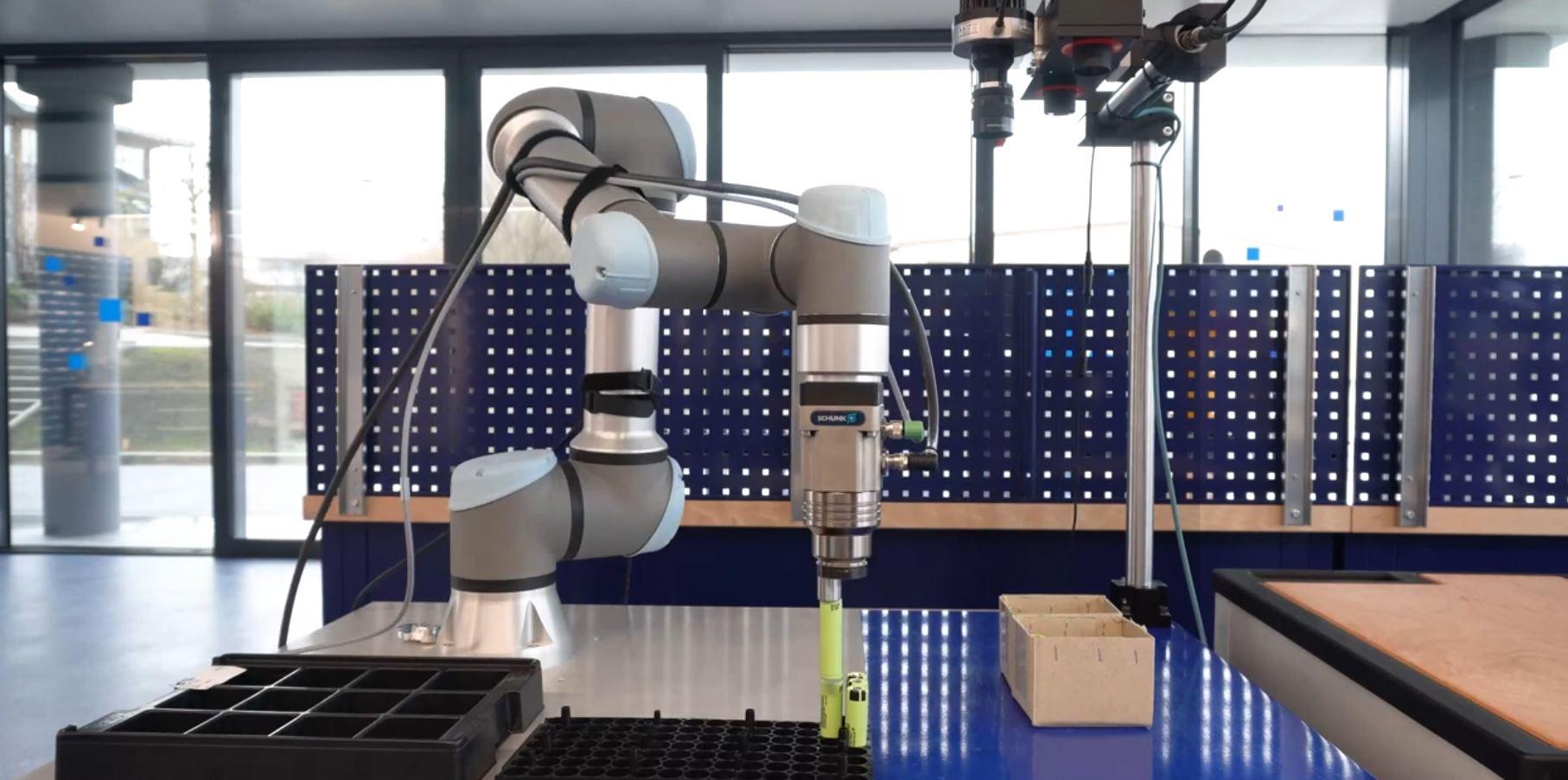

1 / 3Camera-based component separation with 2D camera system and vibration plate

Hardware Price:

DOF

4

ROI

1 - 3

months

Repeatability

0.5

mm

Efficient Metal Part Isolation and Detection with Varioshaker and ifm 2D Camera

Precise detection and separation of components are crucial for streamlining automated processes and ensuring quality control. In this customer test conducted at the igus Customer Testing Area, the Varioshaker isolates metal parts using vibratory movements. Once separated, the parts are analyzed with an ifm 2D camera, which captures and processes their contours with high precision. This setup demonstrates how modern technologies can optimize manufacturing workflows and enhance accuracy.

What is the Application?

The solution automates metal part isolation and detection, providing an efficient system for quality assurance and subsequent robotic handling in manufacturing.

What are the Advantages of the Solution?

Improved Efficiency: Reliable isolation of parts accelerates production cycles.

Enhanced Quality Control: Precise contour detection ensures consistent product standards.

Seamless Integration: Designed for compatibility with automated systems.

What are the Advantages of the Technology?

Both the Varioshaker and the ifm 2D camera excel in performance:

Reliable Separation: The Varioshaker’s vibratory movements ensure accurate part isolation.

High Detection Accuracy: The ifm 2D camera captures detailed contours for precise analysis.

Adaptability: Suitable for integration across different workflows.

Optimizing Automation with Advanced Detection Systems

This test of the Varioshaker and ifm 2D camera showcases how cutting-edge technology can enhance processes in automation. By ensuring efficient isolation and precise detection, it strengthens quality control and simplifies robotic handling, making it a valuable solution for modern manufacturing environments.

3 Components