1 / 3

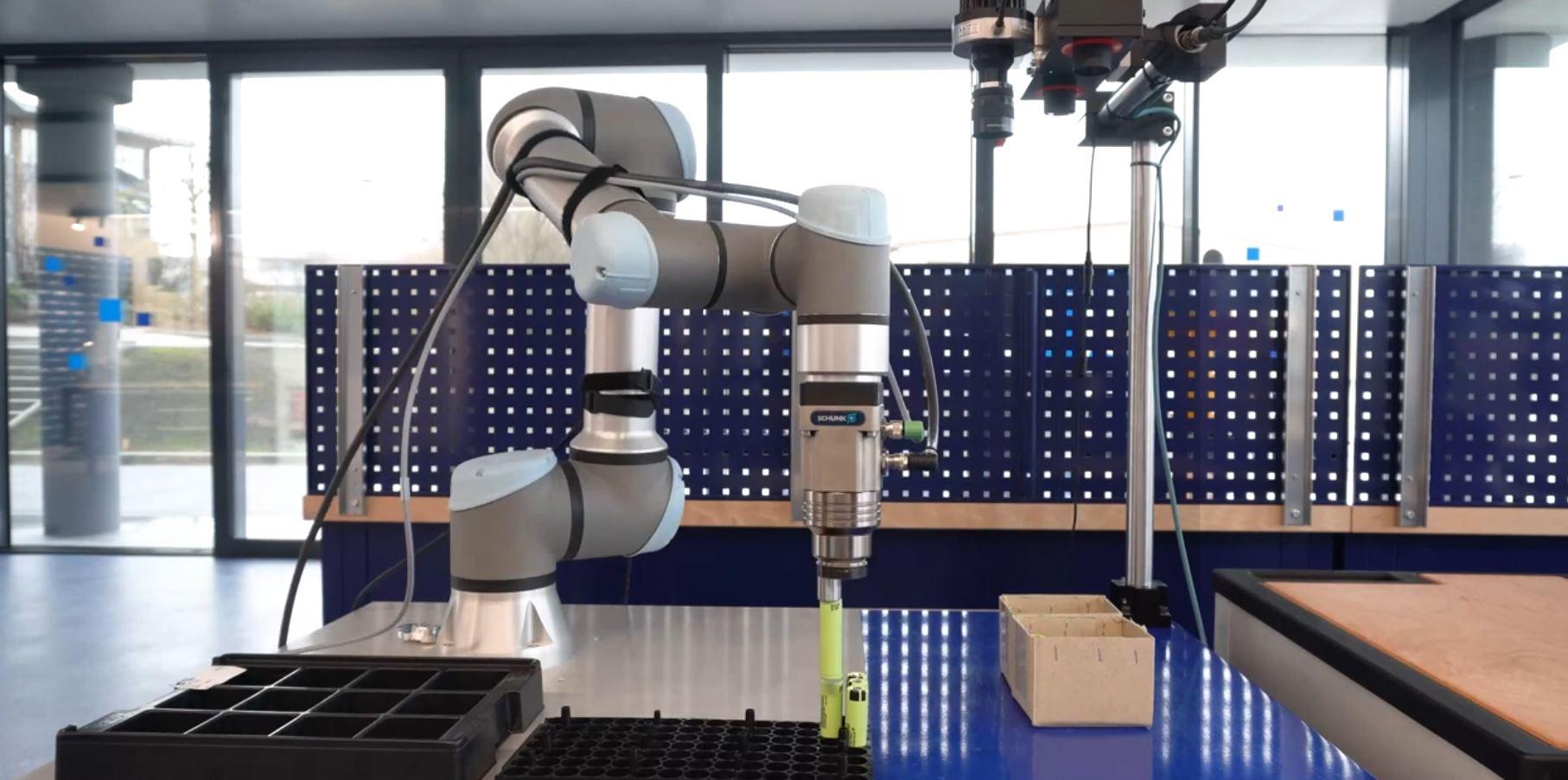

1 / 3Customer test for food industry with FDA compliant gripper

Hardware Price:

Working Space

500x500x100

mm

DOF

3

Repeatability

0.8

mm

Automating Yogurt Cup Handling with igus Gantry and FDA-Compliant Soft Gripper

This video demonstrates a reliable food industry application, showcasing an igus gantry combined with an FDA-compliant soft gripper for handling yogurt cups. The soft gripper gently picks up the cups and places them precisely into cartons, ensuring the process is both smooth and efficient. The igus gantry system offers multi-axis movements, enabling accurate handling, while the FDA-compliant materials ensure food safety standards are met. This setup highlights the performance and reliability of igus solutions in automating delicate tasks within food production workflows.

What is the Application?

The system automates yogurt cup handling and packaging, ideal for food manufacturers seeking precise and hygienic material handling.

What are the Advantages of the Solution?

Food-Safe Materials: Ensures compliance with FDA regulations for hygienic tasks.

High Precision: Accurately places cups for consistent packaging.

Efficient Process: Reduces manual labor while increasing throughput.

What are the Advantages of the Robot?

The igus gantry combined with the soft gripper delivers:

Gentle Handling: Prevents damage to sensitive food products.

Multi-Axis Movement: Versatile positioning for streamlined workflows.

Durable Design: Built for continuous operation in demanding environments.

Streamlining Food Packaging with igus Automation

This yogurt cup handling application demonstrates how igus solutions enhance precision, reliability, and food safety. By automating delicate tasks, manufacturers achieve greater efficiency and compliance, making the igus gantry and soft gripper ideal for optimizing food industry workflows.

3 Components